Guide to Finding Injection Molding Partners in China

The important meeting has recently finished, your new product is a go, the timeline is aggressive, and the budget is… well, let’s just say it’s tight.. Then a voice—perhaps your manager or the CFO—drops the line that gives every project manager a shock: “We should look at sourcing this from China.”

Naturally, you agree. It seems sensible at first glance. The potential savings can be massive. However, your brain is racing with concerns. You’ve heard all the horror stories, right? The quality disasters, the communication black holes, the shipment that shows up three months late looking nothing like the sample. It can feel like you’re being asked to walk a tightrope between landing a huge cost win for the company and steering your project straight into a ditch.

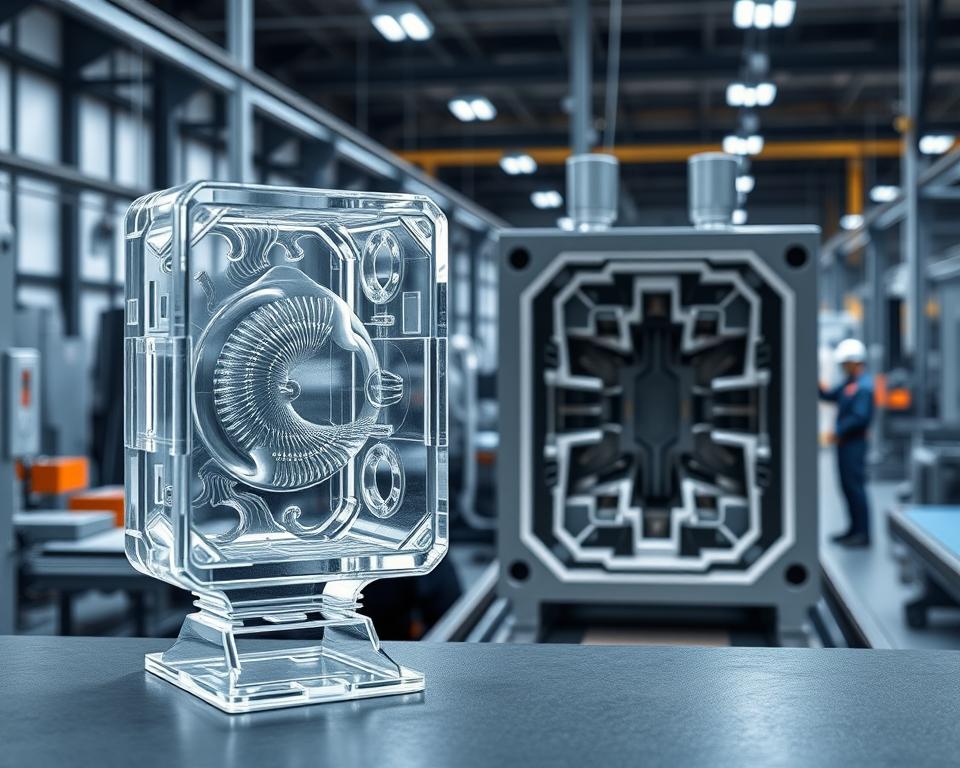

However, here’s the reality. Sourcing plastic mold doesn’t have to be a gamble. It’s a project, just like any other. And like any project, it succeeds or fails based on the process you follow. It’s less about finding the absolute cheapest quote and more about finding the right partner and managing the process with your eyes wide open. Forget the horror stories. Let’s walk through a real-world playbook for getting it right.

First Things First: Your Homework

Before searching suppliers or opening Alibaba, nail down your requirements. Truthfully, over fifty percent of offshore sourcing issues originate in an unclear project brief. You cannot expect overseas partners to interpret your unspoken requirements. A vague RFQ is like telling a contractor to bid on “a house.” You’ll get wildly varied quotes that are useless.

Aim to craft an RFQ package so precise and comprehensive it leaves no room for error. It’s the cornerstone of your entire effort.

What should you include?

Begin with 3D CAD models. They’re essential. Provide files in common formats (e.g., STEP, IGS) to prevent import issues. This is the master blueprint for your part’s geometry.

Yet 3D models don’t cover everything. Include precise 2D engineering drawings. This details critical info missing from the 3D file. I’m talking about critical tolerances (like ‘25.00±0.05 mm’), material specifications, required surface finishes, and notes on which features are absolutely critical to function. Call out smooth surfaces or precision hole sizes in big, bold notation.

Then specify the material. Don’t just say “Plastic.” Nor just “ABS.” Get precise. Specify SABIC Cycolac MG38 in black, if that’s the resin you need. Why? Because there are thousands of plastic variations. Naming the precise grade locks in the mechanical, thermal, and aesthetic properties you need with what is plastic mold.

A good supplier can suggest alternatives, but you need to give them a clear starting point.

Don’t forget the commercial info. What’s your forecasted annual volume (EAU)? They need clarity: is it 1,000 total shots or a million units per annum? The tool design, the number of cavities, and the price per part all hinge on this number.

Hunting for the Best Supplier

With your RFQ perfected, now, who do you send it to? The web is vast but overwhelming. It’s easy to find a supplier; it’s hard to find a good one.

You’ll probably kick off on Alibaba or Made-in-China. They let you survey dozens of suppliers quickly. Treat them as initial research tools, not final solutions. You’ll want to quickly build a list of maybe 10 to 15 companies that look promising.

Still, you must dig deeper. Think about engaging a sourcing agent. They do cost extra. Yet top agents deliver reliable, audited suppliers. They are your person on the ground, navigating the language and cultural barriers. On your first run, this is like insurance. It’s schedule protection.

Also consider trade fairs. If you can attend, shows such as Chinaplas transform sourcing. Nothing beats a face-to-face conversation. You can handle sample parts, meet the engineers, and get a gut feeling for a company in a way that emails just can’t match. Also, leverage the tried-and-true referral network. Consult trusted colleagues. A solid referral can be more valuable than any ad.

Sorting the Contenders from the Pretenders

Now you have your long list of potential suppliers and you’ve sent out your beautiful RFQ package. estimates roll in. Some prices will undercut logic, others will shock you. Your task is to filter them down to 2–3 credible finalists.

How do you do that? It’s a bit of an art and a science.

Step one: audit communication. Are their replies prompt and clear? Is their English good enough for complex technical discussions? But here’s the real test: Are they asking you intelligent questions? Top vendors will critique and inquire. “Have you considered adding a draft angle here to improve ejection?” or “We see your tolerance requirement here; our CMM can verify that, but it will add to the inspection time. Is that acceptable?” This is a massive green flag. It shows they’re engaged and experienced. A supplier who just says “No problem” to everything is a walking red flag.

Next, dig into their technical capabilities. Ask for a list of their equipment. Review examples of parts akin to your design. A small-gear shop won’t cut it for a big housing.

Then comes the audit. This is not optional. You would never hire a critical employee without an interview, so why would you send tens of thousands of dollars for a tool to a company you’ve never truly vetted? Either visit in person or engage a local audit service. They dispatch an on-site auditor for a day. They confirm legitimacy, audit ISO 9001, inspect equipment condition, and gauge the facility. That small investment can save you thousands.

Converting Digital Designs into Molded Parts

You’ve selected your partner. you’ve negotiated the price and payment terms—a common structure is 50% of the tooling cost upfront to begin work, and the final 50% after you approve the first samples. Now the process kicks off.

The first thing you should get back after sending your payment is a DFM report. DFM stands for Design for Manufacturability. This is your supplier’s formal feedback on your part design. They’ll flag thick sections prone to sink, sharp edges that stress, or insufficient draft. A detailed DFM shows expertise. It’s a two-way partnership. You iterate with their team to optimize the mold.

With DFM sign-off, toolmaking begins. In a few weeks, you’ll see “T1 samples are on the way.” These are your initial mold shots. They are your moment of truth.

Expect T1s to need tweaks. This is normal! You’ll find minor defects, off-spec dimensions, or finish issues. You supply feedback, they tweak the tool, and T2 plastic mold samples follow. This process might take a couple of rounds. Plan for this loop in your schedule.

Eventually, you will receive a part that is perfect. Dimensions, finish, and performance all check out. This is your golden sample. You sign off, and it serves as the master quality reference.

Completing the Sourcing Journey

Getting that golden sample feels like the end, but it isn’t. Now you’re entering the mass production phase. How do you ensure that the 10,000th part is just as good as the golden sample?

Implement a robust QC plan. This often involves a pre-shipment inspection. Again, you can hire a third-party service. They’ll sample parts, check dimensions and finish versus your drawings and golden sample, and report. They provide a photo-filled inspection report. Once you sign off, you greenlight shipping and the last payment. This step saves you from a container of rejects.

Don’t forget shipping details. Know your shipping terms. Is your price FOB (Free On Board), meaning the supplier’s responsibility ends when the goods are loaded onto the ship in China? Or is it EXW (Ex Works), where you are responsible for picking it up from their factory door? These details have a big impact on your final landed cost.

Overseas sourcing is a marathon. It’s about building a relationship with your supplier. See them as collaborators, not vendors. Open dialogue, trust, and rigorous procedure deliver results. It’s a challenging project, no doubt. But with this framework, it’s one you can absolutely nail, delivering the cost savings everyone wants without sacrificing your sanity—or the quality of your product. You’re set to succeed.